HACCP

HAZARD ANALYSIS & CRITICAL CONTROL POINT

A HACCP (Hazard Analysis and Critical Control Points) certification helps guarantee that food is safe before distributing it to us. Firstly, a global consensus exists to identify and address any risks associated with the food production process. However, HACCP focuses on identifying the key control points—essential locations where pathogens or chemicals threaten human health. We can ensure food safety by addressing these areas.

In addition, the internet and social media contribute to the rising acceptance of HACCP certification in the contemporary world. Thus, people have higher standards for what they eat and demand that food companies disclose all of their food safety procedures. HACCP guarantees that companies have efficient protocols in place to preserve food safety.

Moreover, firms can profit from having HACCP certification in several ways. Thus, it guarantees that companies follow food safety laws and regulations, sparing them from dealing with problems like fines and recalls. Furthermore, it fosters customer loyalty and improves market competitiveness. Additionally, it aids companies in enhancing their performance by consistently looking for ways to boost output and safety.

HACCP Certification and Auditing Services by CertPro

Companies in the food sector depend more on guidelines like HACCP to guarantee the security of their goods. An essential function of certifications and audits is to confirm that businesses adhere to these requirements. They assess an organization’s adherence to these safety procedures. CertPro can help your business with this procedure; it is well-known for its proficiency in HACCP certification and auditing services. CertPro reduces the possibility of problems with food safety while guaranteeing adherence to safety regulations. Furthermore, CertPro is committed to assisting companies in achieving success while abiding by legal rules and industry standards. CertPro provides customized services to satisfy the demands of different enterprises, regardless of their size or kind.

Why choose CertPro for HACCP certification and auditing?

CertPro is a premier choice for HACCP certification and auditing due to its clear guidance and deep understanding of food safety standards. Our team is well-versed in global requirements for food safety. We tailor solutions to your business’s needs through detailed assessments, expert advice, and efficient problem-solving strategies. Hence, CertPro ensures HACCP compliance, improved food safety measures, customer trust, and operational success, backed by a proven history of achievements. Choose CertPro today for these compelling reasons:

| Factors | CertPro Advantage |

|---|---|

| Time to Certification | 4x faster than traditional approaches |

| Price | Competitive rates with flexible options |

| Process | Streamlined and efficient methodology |

| Expertise | 10+ years of industry experience |

CertPro’s Cost-Effective Approach to HACCP Certification

CertPro’s comprehensive approach ensures a smooth path to HACCP certification. We understand the financial hurdles that businesses face. While we optimize resource allocation and expedite the certification process, we maintain strict compliance standards. This focus on essential areas helps reduce costs by providing customized solutions. CertPro supports businesses in achieving HACCP certification, guaranteeing information security compliance while maximizing budget efficiency. Therefore, CertPro is the preferred choice for cost-effective HACCP compliance solutions.

| No. of employees | Timeline | Cost (approx.) |

| 1 – 25 | 4 weeks | 2500 USD |

| 25-100 | 6 weeks | 3500 USD |

| 100-250 | 6-8 weeks | 5000 USD |

| 250 plus | 8 weeks | Custom plans |

UNDERSTANDING THE FUNDAMENTALS OF HACCP

The HACCP technique protects our food by identifying possible risks like chemicals, germs, or other dangerous materials. It covers all parts of food, from where it comes from to how it’s prepared, stored, and eaten. Firstly, HACCP finds these hazards and checks how serious they could be. Then, it makes rules to reduce or altogether remove these dangers. After all, the primary goals are to keep us healthy and ensure people trust that our food is safe.

In the food industry, HACCP is used on farms, factories, packing, transportation, and restaurants. Therefore, to work well, several steps must be followed. First, it looks for dangers and checks how serious they might be. Then, it sets up rules to control or eliminate these risks and ensures they are followed. Finally, it keeps improving by learning new skills and finding better ways to keep food safe.

Before starting HACCP, companies must perform essential maintenance, ensure workers’ health, and fix broken equipment. Again, these basic steps create the right conditions for HACCP to work well. Moreover, they reduce risks and ensure everything goes smoothly by following the HACCP rules and keeping food safe.

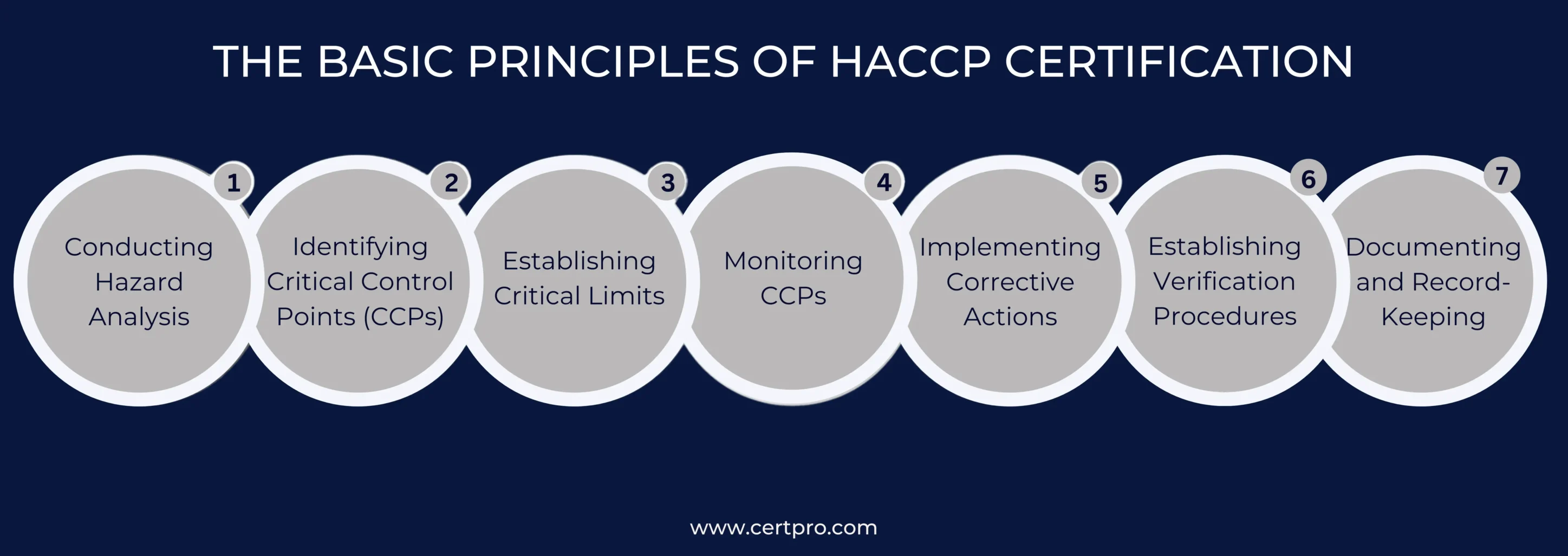

THE BASIC PRINCIPLES OF HACCP CERTIFICATION

The basic ideas of HACCP (Hazard Analysis and Critical Control Points) certification are the starting point for keeping food safe systematically. These ideas help companies set up an excellent system to ensure safe food. Here are the main principles of HACCP certification:

1. Conducting Hazard Analysis: First, examine each food-making step to identify potential hazards. This helps determine which hazards are essential and need to be controlled.

2. Identifying Critical Control Points (CCPs): CCPs are specific times during food production when you do things to stop or lessen hazards. This is important for keeping dangers under control.

3. Establishing Critical Limits: The highest and lowest values keep the CCPs working well. They are based on science and rules to ensure safety.

4. Monitoring CCPs: Companies regularly check CCPs to ensure they follow the limits. This means measuring or watching closely to catch any problems early.

5. Implementing Corrective Actions: If something goes wrong at a CCP, companies have to fix it immediately. As a result, it finds out why it happened, fixes it, and ensures it doesn’t happen again.

6. Establishing Verification Procedures: Checking is important to ensure the whole HACCP system works properly. This includes reviews, tests, and audits to keep everything in line.

7. Documenting and Record-Keeping: Companies keep detailed records of everything they do with HACCP. This includes what hazards they find, what CCPs they use, and all the checks and fixes they make. It helps ensure everyone knows what’s happening and proves they follow the rules.

By following these principles, companies can manage dangers well and ensure their food is safe and quality, keeping people healthy.

THE PROCESS INVOLVED IN HACCP CERTIFICATION

Getting HACCP certified involves several steps and takes time. It requires careful planning, commitment to management, and the involvement of knowledgeable people who understand HACCP principles. Let’s look at how to get certified:

Step 1: Understanding the Requirements of HACCP: Organizations must understand and follow HACCP rules to meet regulations. With the assistance of the International HACCP Alliance, organizations can acquire knowledge of these regulations by enrolling in approved courses such as those offered by HACCP Mentor. If needed, they can also hire an expert in food safety.

Step 2: Make a HACCP Plan: Create a specific plan for your business and products, considering your country’s laws and any places you export. Then, implement the plan carefully and define what it covers, including areas, products, processes, and locations. This is crucial for audits.

Step 3: Perform a Gap Analysis: If your company already has a HACCP plan, use it to identify any standard requirements that were overlooked. To guarantee complete compliance, you can complete this internally or with assistance from a food safety professional.

Step 4: Choose a Certification Body: Choose a trustworthy certifying body with auditors who assess HACCP plans. Make sure they are accredited to provide this certification service.

Step 5: Undergo the HACCP Audit: Finally, undergo a thorough audit, during which auditors review your food safety practices. This usually includes checking documents remotely and visiting your site. They’ll follow up to ensure any significant issues are fixed.

HACCP CERTIFICATION REQUIREMENTS

Organizations must adhere to strict guidelines that guarantee food safety and production that meets high standards. What the organizations should do is as follows:

Develop an Effective HACCP Plan: organizations must draft a thorough strategy known as a HACCP plan. This plan finds and eliminates any hazards in the food preparation process from beginning to end.

Provide a Comprehensive Product Description: Businesses must provide full details about their products, including their composition, ingredient usage, and processing method.

Identify the Product’s Intended Use: Manufacturers should know how their products will be utilized. This aids their ability to identify potential threats and implement the appropriate safety precautions.

Create Procedures and Plans Aligned with HACCP: Organizations must develop plans and procedures that adhere to HACCP guidelines. Therefore, any threats that are discovered must be addressed by these plans.

Identify and List All Hazards and Critical Control Points (CCPs): They should also compile a list of every risk and the CCPs (critical control points) requiring the most significant safety precautions. This contributes to food safety throughout its manufacture.

Establish Limits for Each CCP Based on the Specific Food: Organizations must also determine CCP limitations according to the type of food being prepared. These boundaries ensure that the safety precautions are effective in thwarting any threats.

Define Specific Corrective Actions for Deviations: Businesses must have a plan to address any issues that arise and ensure safety limitations are not reached. However, this includes determining the cause, resolving the problem, and taking precautions to ensure it doesn’t occur again.

Create a Verification Procedure: The organization must also ensure its HACCP system operates effectively. This entails conducting routine inspections, evaluations, and testing to guarantee security.

Implement Accurate Record-Keeping Practices: Organizations must record everything they discover regarding possible risks, safety measures, and actions to guarantee food safety.

Perform Internal Audits: Companies must routinely examine internally. This enables them to ensure that all regulations are being followed, identify areas for improvement, and maintain food safety for all.

By taking all these steps, organizations demonstrate their seriousness about maintaining food safety. This aids in their HACCP certification, proving that they adhere to strict guidelines for food safety. It ensures that the food they produce is safe to consume and reduces the hazards for all those who prepare and market food.

THE KEY BENEFITS OF HACCP CERTIFICATION

HACCP certification helps in several ways to ensure food safety and quality:Enhances food safety standards, ensuring the food products are safe for consumption.

- It guarantees that food products are safe to eat.

- Ensures businesses comply with food safety laws to avoid penalties.

- It raises food quality standards, making products better and pleasing customers.

- Demonstrating commitment to food safety boosts market value and competitiveness.

- It provides a structured plan to produce safe, high-quality food.

- Identifying and controlling hazards reduces the risk of foodborne illnesses and product recalls.

- It promotes teamwork and efficiency by assigning clear roles for food safety.

- Preventing issues like recalls or contaminated products saves time and money.

VALIDITY OF HACCP CERTIFICATION

Businesses need HACCP certification to prove their reliability in maintaining food safety. A company’s rules define how and by whom it can be certified, and this validity usually expires after one to three years. For the business’s certification to remain valid during this period, it must constantly abide by the rules. The certifying agency regularly inspects it to ensure everything remains safe.

If you’re wondering how long does it take to get HACCP certification, it typically takes about one to six months, depending on the size and complexity of the business. A valid HACCP certification shows that the business cares greatly about food safety and proves to customers, regulators, and others that the industry knows how to keep food safe from start to finish. When the certification period ends, the company needs to renew it. This shows that the organization is still committed to keeping food safe and following all the rules.

FACTORS INFLUENCING HACCP CERTIFICATION COST

A few factors determine how much it costs to become HACCP-certified. First, the organization’s size and complexity are equal. Similarly, larger organizations with multiple locations and intricate supply chains may be required to pay a higher certification fee. After that, it concerns what kind of business it is and how dangerous the food they create is. Therefore, certain companies may pay more for certification because they require more audits and testing. Moreover, the certifier has an impact on price as well. Consequently, various establishments can charge varying fees for assurances that everything is secure.

Additional factors that may impact the cost include the requirement for further training or documentation assistance. However, companies should consider all of these factors and obtain guides from sources that can validate them. After that, the organization can then budget for the expense of certification by determining how much it will cost.

CERTPRO: ENABLING BUSINESSES TO ACHIEVE HACCP CERTIFICATION WITH CONFIDENCE

CertPro helps businesses get HACCP certification by offering audits, consulting, and certification services. Our team of experts guides businesses through setting up the HACCP system. In addition, we check everything carefully, find the critical safety points, and help put plans in place to keep food safe. CertPro also helps with paperwork, training, and ensuring the plans fit your business. Working with CertPro shows that your company follows the HACCP rules, makes food safer, and meets all the laws. Certified with CertPro makes customers trust you more and helps you improve in the food industry.

FAQ’s

HOW LONG DOES IT TAKE TO OBTAIN HACCP CERTIFICATION?

The duration of the certification process depends on the organization’s readiness and the complexity of its operations. It usually lasts between a few months and a year. The organization must undergo a series of assessments, audits, and documentation reviews to demonstrate compliance with HACCP requirements.

WHAT HAPPENS AFTER OBTAINING HACCP CERTIFICATION?

After obtaining HACCP certification, the organization must adhere to the HACCP principles and requirements. It involves ongoing monitoring, maintenance of records, periodic internal audits, and participation in surveillance audits conducted by the certification body.

DOES HACCP CERTIFICATION GUARANTEE FOOD SAFETY?

While HACCP certification demonstrates an organization’s commitment to food safety and compliance with HACCP principles, it does not guarantee absolute food safety. Certification assures that the organization has implemented effective control measures, but proper implementation and ongoing adherence to the HACCP plan are crucial for ensuring food safety.

IS HACCP CERTIFICATION MANDATORY?

The requirement for HACCP certification can vary depending on local regulations and industry standards. In some cases, HACCP certification may be mandatory for some sectors, such as food manufacturing or processing. And it is essential to research and understand the specific requirements of your industry and jurisdiction.

WHAT ARE THE DIFFERENT TYPES OF FOOD HAZARDS IN HACCP, AND HOW DO THEY POSE RISKS TO FOOD SAFETY?

The types of food hazards in HACCP include biological Hazards (such as bacteria, viruses, and parasites), chemical hazards (such as toxins and contaminants), and physical hazards (such as glass, metal, or foreign objects). These hazards can pose risks to food safety and must be identified and controlled in the HACCP system.

NAVIGATING DATA PRIVACY FRAMEWORKS: A COMPREHENSIVE GUIDE

Globalization has intense effects on business functioning and scaling. In today's digital world, companies are generating an unprecedented rate of data that requires protection from emerging cyber threats. In addition, recurring data breaches and privacy concerns make...

BUSINESS NON-COMPLIANCE: THE HIDDEN FINANCIAL AND OPERATIONAL COSTS

Businesses are always in a dilemma regarding whether or not to be compliant. Most companies think that compliance will problematize their operating process. However, highly regulated industries like financial and healthcare services meet the legal obligations for...

Security Frameworks: A Comprehensive Guide with 14 Examples

Technological advancements make cyberattacks more sophisticated and advanced. Hence, organizations must keep up with the latest cybersecurity frameworks in these complicated scenarios to sustain themselves in a dynamic threat environment. Different cybersecurity...