ISO 13485:2016

MEDICAL DEVICES – QUALITY MANAGEMENT SYSTEM

The medical industry operates under strict regulations to ensure device quality and safety. Compliance is crucial, and that’s where ISO 13485 certification comes in. It brings many benefits to organizations. Despite needing initial effort, this system improves operations, sales, and customer satisfaction. Additionally, the ISO 13485 certificate provides a structured framework. This helps companies comply with directives, regulations, protocols, and responsibilities. It ensures manufacturers deliver safe, high-quality devices.

ISO 13485 is an internationally recognized standard for device manufacturing quality and safety. Having this certification helps companies gain recognition as reputable, trustworthy providers. It’s valuable regardless of company size or location. This standard ensures all devices effectively meet regulatory laws and customer needs. Thus, ISO 13485 stands out as the optimal medical device standard in the industry. It is essential for professionals and customer safety in clinics, hospitals, and other medical settings.

ISO 13485:2016 Certification and Auditing Services by CertPro

CertPro offers an affordable choice for ISO 13485 certification. We understand the need to manage certification fees while being compliant. Therefore, our tailored services reduce unnecessary expenses and the burden of compliance. We accelerate the certification process by utilizing the resources that reduce costs. Thus, CertPro’s low-cost structure and efficient methods make ISO 13485 certification accessible. However, we maintain the audit quality process and practical suggestions. CertPro is a reliable source for achieving ISO 13485 certification on a budget.

Why choose CertPro for ISO 13485:2016 certification and auditing?

CertPro is the best choice for ISO 13485 certification and auditing for various convincing reasons. Our knowledgeable staff will provide personalized guidance in the complex certification process. We also strictly follow data protection and legal rules while putting your business needs first. CertPro’s track record shows you care about protecting client data, building trust, and lowering risks. It helps you to establish yourself as a responsible and well-respected industry pioneer.

| Factors | CertPro Advantage |

|---|---|

| Time to Certification | 4x faster than traditional approaches |

| Price | Competitive rates with flexible options |

| Process | Streamlined and efficient methodology |

| Expertise | 10+ years of industry experience |

CertPro’s Cost-Effective Approach to ISO 13485:2016 Certification

CertPro provides an innovative, low-cost approach to obtaining ISO 13485 certification. We consider compliance’s limited resources and adjust services to save money and time. Our skilled auditors focus on essential areas and skip unnecessary auditing steps. CertPro allows you to protect client data, excel competitively, and achieve regulatory goals.

| No. of employees | Timeline | Cost (approx.) |

| 1 – 25 | 6 weeks | 4750 USD |

| 25-100 | 8 weeks | 6750 USD |

| 100-250 | 8-10 weeks | 9750 USD |

| 250 plus | 12 weeks | Custom plans |

Overview of ISO 13485: 2016 Understanding the International Standard for Medical Devices

It is an essential ISO standard for medical devices that was created using ISO 9001. Accordingly, it contains the core ideas of the ISO Quality Management System. Manufacturers of medical devices benefit from this standard and can set up efficient procedures. Consequently, it guarantees that specific procedures are maintained. Its primary objective is to harmonize medical device regulatory requirements. Thus, it encompasses particular mandates for the manufacturing, installing, and servicing of medical devices. Therefore, the standard emphasizes on:

- Implementing a Quality Management System with several enhancements

- Adopting a risk management approach to product development and realization

- Validating processes to ensure effectiveness

- Complying with statutory and regulatory requirements.

- Establishing efficient product traceability and recall systems

By adhering to ISO 13485, companies can reduce safety and legal risks while creating more efficient work environments. This standard ensures quality and safety in medical devices. Thus enhancing a company’s reputation and trustworthiness in the market. The standard is reviewed every five years to address evolving requirements and industry needs.

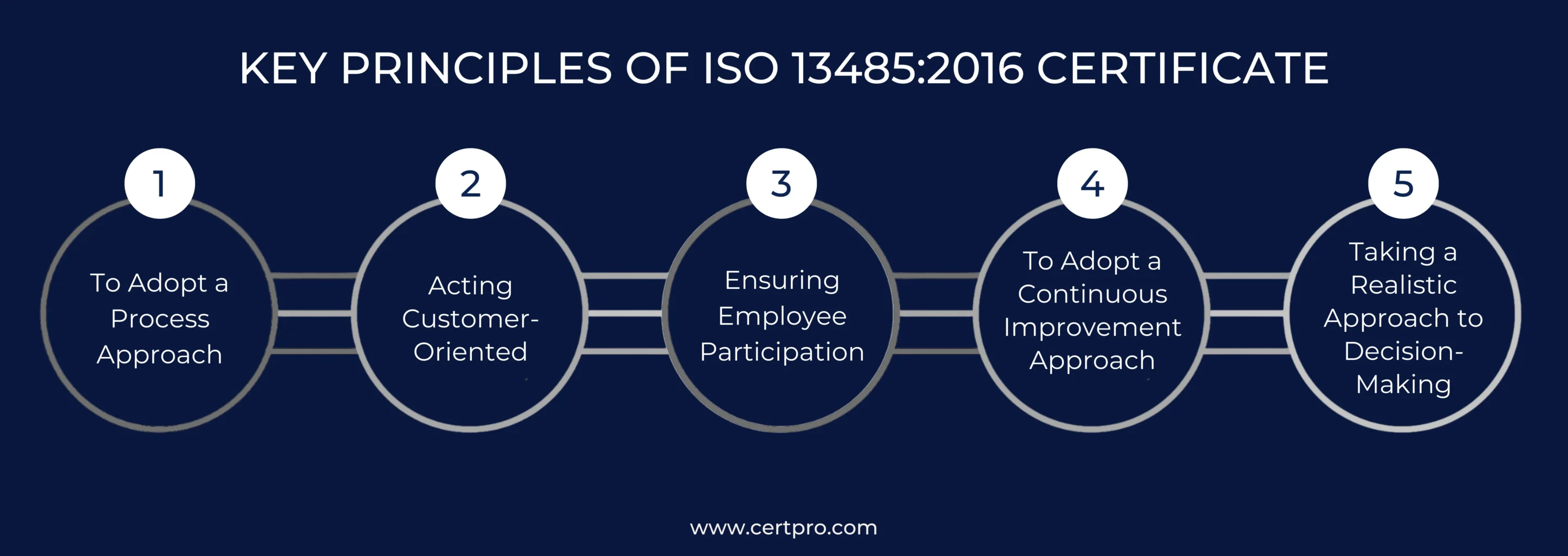

KEY PRINCIPLES OF ISO 13485:2016 CERTIFICATE

The basic principles of the ISO 13485 Medical Device Quality Management System are as follows:

- To adopt a process approach

It includes adhering to procedures, job descriptions, workflows, and application instructions outlined in the standard. Efficient resource utilization is a key focus. It enables timely recognition of potential risks and facilitates prompt response to hazards. The standard allows for proactive measures to avoid unforeseen situations.

2. Acting customer-oriented

Businesses that value the customer at their center always stay one step ahead. Meeting customer needs and expectations becomes essential. Giving importance to customers is necessary to create customer satisfaction. It builds reliance, gains a respectable and prestigious position in the market, and takes the lead in the competition with rivals.

- Ensuring employee participation

Making sure employees take part is a fundamental concept that stresses getting all employees involved and making them more aware. It is an essential idea that all management methods must follow. When workers aren’t involved, they don’t own or take responsibility for fixing problems, and the team needs to work better together. On the other hand, workers should be accountable for how well they do their jobs. Then, workers feel like they are an essential part of the company, work harder, and take more initiative.

- To adopt a continuous improvement approach

This principle is essential for ensuring the ongoing performance of the enterprise. Every company worker should look for ways to improve services, methods, or systems. With this commitment, the company can act quickly and adaptably to new possibilities. The ISO 13485 Medical Devices Quality Management System agrees with this basic idea.

- Taking a realistic approach to decision-making

Enterprises should make data-based and rational decisions to avoid unpredictable situations. An organization must utilize and analyze all the data from its activities to make accurate and effective decisions.

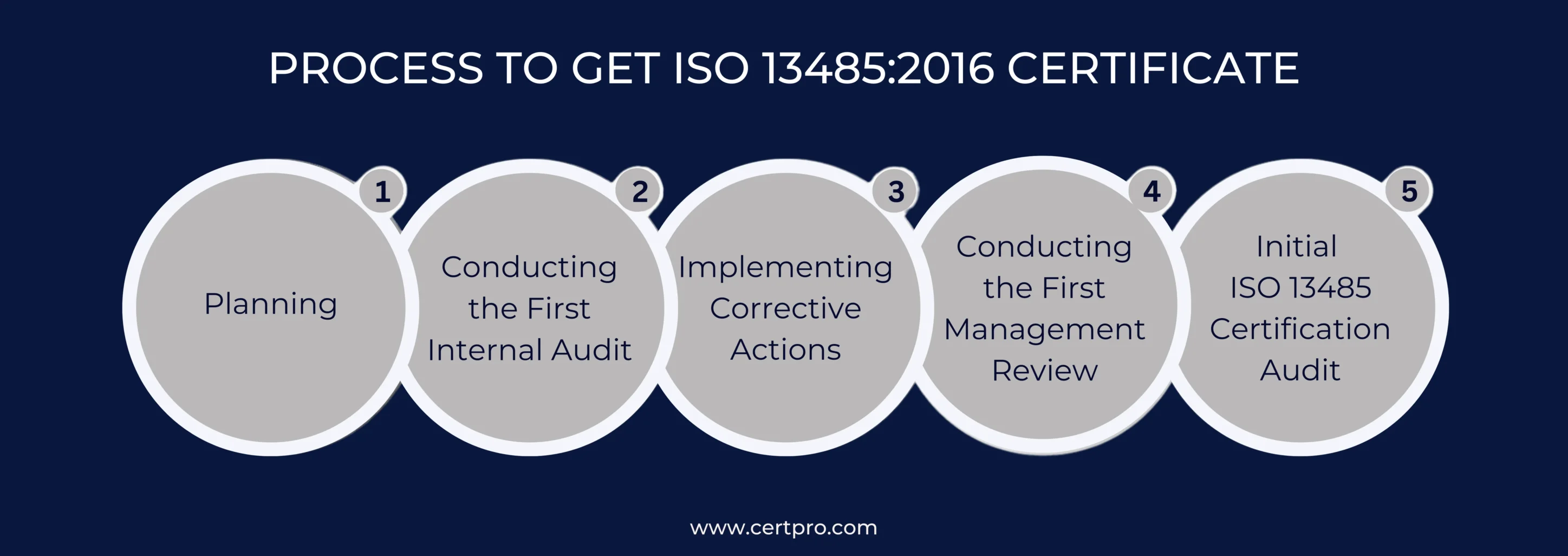

PROCESS TO GET ISO 13485:2016 CERTIFICATE

While the specific requirements and initial steps on how to get ISO 13485 certification may vary, here are the following steps to get started:

Step 1: Planning

At this stage, an organization develops a plan for establishing a Quality Management System (QMS) that aligns with the quality planning requirements of the ISO 13485 standard. It includes creating a quality manual and implementing an optimized method for documenting quality plans when making changes to the QMS. In addition, the organization has to complete the following tasks:

- Obtain the ISO 13485 standard and related documents.

- Identify and establish relevant processes.

- Assign internal auditors and teams to oversee these processes.

- Create a schedule, define workflows, and establish guidelines for each process.

- Conduct gap analysis for each process or task.

- Providing ISO 13485 certification training for process owners

- Enhance and finalize processes.

- Standardize processes and document necessary records.

Step 2: Conducting the First Internal Audit

Conduct the first internal audit to verify the effectiveness of your QMS before the external audit. This enables the identification of nonconformities and the development of appropriate mitigation actions.

Step 3: Implementing Corrective Actions

After reviewing the internal audit report, you can identify any issues or areas that require improvement. Initiate a Corrective and Preventive Action (CAPA) process to address these. This quality management procedure enables the implementation of necessary actions and process improvements.

Step 4: Conducting the First Management Review

The organization’s quality objectives must be reviewed before the third-party audit. After that, management concludes by finalizing a list of action items, and changes are made based on internal audit findings. This list serves as a guide for the subsequent management review before applying for certification.

Step 5: Initial ISO 13485 Certification Audit

In this step, your organization must select a recognized ISO 13485 certification body to conduct the audit. The application for certification begins, including filling out and reviewing the form before submission to the certification body. Therefore, contract signing may also occur during this stage. This step consists of two phases:

Stage 1: Documentation Survey: The third-party auditor assesses the organization’s system documentation. Various documents must be prepared, including the quality manual, organizational chart, internal auditing process and schedule, CAPA protocols and log, and management review findings and process.

Stage 2: Primary Audit: It verifies that the organization satisfies the ISO 13485 certification requirements and complies with international market regulatory requirements. The auditor evaluates the effectiveness of your quality system by sampling records from each implemented process. Additionally, this stage determines the schedule for surveillance audits (typically conducted annually) and reassessments.

THE ISO 13485:2016 REQUIREMENTS

The ISO 13485 standard contains eight sections (clauses). The first three clauses explain the scope, reference, definition, and other general information. The last five clauses are as follows:

Clause 4: Quality Management System

It targets two specific aspects: General Requirements and Documentation Requirements.

General Requirements: The general requirements dictate that organizations implement a quality management system. Therefore, adherence to the standard provides risk management.

Documentation Requirements: ISO 13485 requires that medical device manufacturers create a quality manual. Thus, maintain product specifications and guidance, implement a document control plan, and establish a record control plan for data integrity and security.

Clause 5: Management Responsibility

The Management team of an organization implementing ISO 13485 must demonstrate specific responsibilities. They focus on the end user’s needs and ensure compliance with rules. Although the certification monitors manufacturing and emphasizes employee quality policies and procedures, it also reviews system improvements, such as the Management Review, for better results.

Clause 6: Resource Management

Top management must provide the essential resources to ensure compliance with ISO 13485. Therefore, they must also support the quality system throughout the organization by assigning proper personnel, infrastructure, tools, and equipment, succession planning, and risk aversion planning. Implementing a quality system requires more than just implementing it.

Clause 7: Product Realization

Developing a new product encompasses the entire process, from conceptualization to design and implementation. In addition, ISO 13485 certification stresses the following processes throughout a product’s life cycle. Thus, it confirms that an organization follows a robust system to ensure customer satisfaction.

Clause 8: Measurement, Analysis, and Improvement

ISO 13485 emphasizes the significance of tracking customer feedback and monitoring product performance. Therefore, this process helps manage compliance and informs the regulatory authorities while identifying non-conforming products. Thus, the certification monitors product performance while striving to improve processes.

BENEFITS OF ISO 13485:2016 CERTIFICATION

There are various advantages to manufacturing medical devices using ISO 13485.

Enhanced Customer Satisfaction: It guarantees the regular provision of dependable goods and services in the medical field.

Cost Savings: Continuously improving processes improves operational efficiency, which lowers operating expenses.

Strengthened Stakeholder Relationships: The certification helps develop partnerships among the stakeholders.

Compliance with Legal Regulations: ISO 13485 lowers legal risks by adhering to regulatory compliance.

Established Business Credibility: A certification provides proof of a company’s commitment to quality. It creates a pathway to raise its credibility.

Competitive Advantage in Regulated Sectors: ISO 13485 certification gives you a competitive advantage.

Enhanced Risk Management: Improved product traceability and uniformity help in risk management.

ISO 13485:2016 CERTIFICATION COST

ISO 13485 certification cost depends on several factors. Firstly, it depends on the size of your company. Additionally, the number of sites needing certification plays a role. The types of products and services you offer also influence the cost. Moreover, the total number of employees is a factor. Ensuring compliance with ISO 13485 involves various expenses. These include training staff and adjusting processes. Administrative costs and early assessments are also necessary. Sometimes, hiring specialists becomes essential. Despite their expense, consultants ensure compliance. They speed up processes and minimize risks effectively. ISO 13485 emphasizes quality, risk management, and meeting regulations. Therefore, seeking professional advice is crucial for accurate cost estimation.

Validity Period of ISO 13485:2016 Certification: Certification Duration and Renewal

The certificate is valid for three years. After ISO 13485 certification, the organization undergoes yearly checks. Moreover, these audits ensure the system works well and confirm compliance with ISO standards. Firstly, these evaluations provide a complete assessment to see if the company meets ISO 13485 criteria. Additionally, this recurring evaluation shows the organization’s dedication to upholding certification. Therefore, when the three-year period ends, a recertification audit takes place. This audit checks for ISO 13485 renewal and continuous compliance. The ISO 13485 certificate must be verified for the firm to maintain compliance. Ultimately, it ensures that operational procedures are high-quality and requirements are continuously met.

ISO 13485:2016 CERTIFICATION Simplicity: PARTNERING WITH CERTPRO FOR SUCCESS

CertPro offers comprehensive auditing, consulting, and certification services. Our experienced team specializes in ISO 13485 standards. We assist businesses in navigating certification processes. Moreover, CertPro ensures adherence to industry norms and global standards. Therefore, we evaluate and optimize quality management systems for medical devices. CertPro provides detailed documentation and training to enhance compliance and operational efficiency. Partnering with CertPro underscores its commitment to quality and regulatory compliance. Collaboration with us boosts credibility and market access. Achieve ISO 13485 certification with CertPro, fostering client satisfaction and industry recognition.

FAQ’s

HOW LONG DOES IT TAKE TO OBTAIN ISO 13485:2016 CERTIFICATION?

The time required for ISO 13485 certification depends on various factors, including the organization’s readiness and the complexity of its quality management system. Typically, it can take several months to implement the necessary processes, undergo audits, and address any non-conformities identified.

WHAT HAPPENS After OBTAINING ISO 13485:2016 CERTIFICATION?

After achieving ISO 13485 certification, the organization should maintain and improve its quality management system. It involves conducting regular internal audits, addressing non-conformities, monitoring customer feedback, and participating in surveillance audits by the certification body.

IS ISO 13485 CERTIFICATION MANDATORY FOR MEDICAL DEVICE MANUFACTURERS?

ISO 13485 certification is not required in all countries. However, it is well-known and frequently required by regulatory bodies and clients in the medical device industry as proof of compliance with quality standards.

CAN ISO 9001 CERTIFICATION BE USED AS A SUBSTITUTE FOR ISO 13485 CERTIFICATION?

While ISO 9001 and ISO 13485 share similarities, ISO 9001 focuses on general quality management principles, while ISO 13485 specifically addresses the requirements for medical device manufacturing. Depending on the regulatory and customer requirements, ISO 9001 certification may not be sufficient, and ISO 13485 certification may be necessary.

WHAT IS THE ROLE OF A CERTIFICATION BODY IN THE ISO 13485 CERTIFICATION PROCESS?

A certification body is an independent organization that assesses an organization’s compliance with ISO 13485. They conduct audits, review documentation, and issue the ISO 13485 certificate if all requirements are satisfied. It is necessary to choose a reputable and accredited certification body.

NAVIGATING DATA PRIVACY FRAMEWORKS: A COMPREHENSIVE GUIDE

Globalization has intense effects on business functioning and scaling. In today's digital world, companies are generating an unprecedented rate of data that requires protection from emerging cyber threats. In addition, recurring data breaches and privacy concerns make...

BUSINESS NON-COMPLIANCE: THE HIDDEN FINANCIAL AND OPERATIONAL COSTS

Businesses are always in a dilemma regarding whether or not to be compliant. Most companies think that compliance will problematize their operating process. However, highly regulated industries like financial and healthcare services meet the legal obligations for...

Security Frameworks: A Comprehensive Guide with 14 Examples

Technological advancements make cyberattacks more sophisticated and advanced. Hence, organizations must keep up with the latest cybersecurity frameworks in these complicated scenarios to sustain themselves in a dynamic threat environment. Different cybersecurity...